Hoʻohana ka ʻoihana hoʻopaʻa i ka Tungsten Carbide Cold Forging Die

1. ʻO ka hale hana Kina i kūikawā i ka hana a me ka hanaʻana, ISO certification.

2. Nui nā nui a me nā ʻano i loaʻa no OEM.

3. Hana ʻia me 100% mau mea waiwai kiʻekiʻe

4. Hui hana 'oihana, lawe wikiwiki

5. ʻOihana manuahi ma hope o ke kūʻai aku a me ke kākoʻo ʻenehana

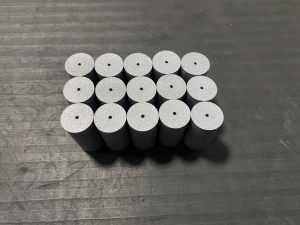

Hoʻohana nui ʻia ʻo Tungsten carbide anuanu poʻo no ka hana ʻana i ka pau ʻana o ka hoʻoheheʻe ʻana i ka mold, make punch, uea kiʻi make, machine mold, progressive die, extrusion die, press mold, mold parts, trimming die, cold heading die, forging mold, anu make make. etc.

| ʻO Tungsten Carbide Cold Forging/heading Make | |||||

| Papa helu | ʻO ka mānoanoa | TRS | ʻoʻoleʻa | Paipai ʻia ka hana a me ka noi | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Hoʻokumu a hoʻopaʻa ʻia paha i make no nā pauka metala a me nā pauda nonmetal. | |

| YG15 | 14 | ≥3400 | 87.5 | No ka hana ʻana i ke kaha kiʻi make o nā paipu kila a me nā koʻokoʻo ma lalo o High compressibility ratio;ke kuʻi ʻana, ke kuʻi ʻana, nā mea hana forging ma lalo o ke koʻikoʻi nui. | |

| YG20 | 13.5 | ≥3800 | 85.5 | No ka hana ʻana i nā mea hoʻoheheʻe ʻia no nā ʻāpana wati, nā pā puna o nā mea kani, nā ipu pākaukau, nā pōlele kila liʻiliʻi, nā ʻūlū, nā pāpale wili. | |

| YG15C | 14 | ≥4000 | 86.5 | No nā ʻāpana ʻaila cone drill, ʻoki i nā pōhaku palupalu a paʻakikī; ka wehe ʻana a me ka ʻoki ʻana i ka lāʻau maloʻo, ka lāʻau palupalu a me ka lāʻau kumu. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging make. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging make, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Make no ka hoʻohana pale ʻana a i ʻole ka hopena hopena. | |

| YG22C | 13.3 | ≥4000 | 83 | ʻO ka make ʻana o ka nut a me ke kūpaʻa kiʻekiʻe o ka make forging. | |

| YG25C | 13.1 | ≥4250 | 82.5 | ʻO ke poʻo poʻomanaʻo bolt kuhiliʻole make a me nā wili. | |

Hoʻohālikelike Mea → Ka Mīkini Pōʻani Wet → Hoʻohui ʻia ʻo WC a me ka Mana Cobalt → Paʻi → Nā kapuahi Sintering HIP → ʻIke QC → Hoʻopili

| ʻAno | OD | ID | H | Hoʻomanawanui | ||

| OD | Id | H | ||||

| φD10~14×φd | 10~14 | 1.0~5.0 | 15~40 | D×+3% | d×-3% | H×+3% |

| φD15~24×φd | 15~24 | 1.5~8.0 | 20~60 | |||

| φD25~40×φd | 25~40 | 1.5~25 | 30~60 | |||

| φD42~95×φd | 42~95 | 2.0~50 | 20~95 | |||

No nā nui ʻē aʻe hiki iā mākou ke hana maʻamau e like me nā koi a nā mea kūʻai aku a i ʻole nā kiʻi.

1. E ho'āʻo mākou i ka mea maikaʻi loa e pane i kā mākou customers'request i loko o 24hours.

2. E mālama mākou i nā kamaʻilio kūpono a maikaʻi me kā mākou mea kūʻai.

3. Hāʻawi mākou i ka mana maikaʻi o ka papa mua a me nā lawelawe ma hope o ke kūʻai aku.

E hāʻawi mākou i ka ukana i hana ʻia i loko o 30 mau lā ma hope o ka uku ʻana, ʻoiai, inā he noi soecific i ka manawa hoʻouna.Hiki iā mākou ke hoʻololi e like me ke noi a nā mea kūʻai aku, no laila, loaʻa loa ka manawa hāʻawi pōkole.

ʻO ka maʻamau 30% T / T ma mua, kaulike 70% ma mua o ka lawe ʻana.Hiki ke hoʻololi e like me ke noi o nā mea kūʻai aku.

Hana mākou i nā ʻāpana i nā ʻano like ʻole a me nā nui e kūlike i nā koi o kā mākou mea kūʻai aku, inā pono lākou i nā poloka a i ʻole nā pepa, nā cylinders, nā bearings, nā ʻōlelo a me nā niho.